In a world where almost everyone has a consent decree that mandates analyzer drift checks, it is important that we understand and work to prevent any failures. Regardless of which analyzer is being used, here are some quick things to look for in order of frequency:

In a world where almost everyone has a consent decree that mandates analyzer drift checks, it is important that we understand and work to prevent any failures. Regardless of which analyzer is being used, here are some quick things to look for in order of frequency:

Leaking Probes:

A leak in your sample delivery system introduces an inconsistent level of ambient air into the sample line during calibration or drift. You have created an accidental dilution probe.

Best Practice:

Inspect and confirm that all o-rings are in pristine condition every day. Put your finger over the probe tip and confirm that there are no leaks in the probe hose, the probe fittings or the inlet filter.

Contaminated Gas Bags:

At 4:00 AM, with a dozen analyzers to calibrate, 500PPM can look a lot like 5000PPM. One misfilled bag could require re-monitoring of the day’s work.

Best Practice:

Carefully inspect each bag and each valve. Make sure that you properly filled and labeled each bag. (Very Best Practice: Stop using gas bags! LDARtools SpanBox and Cal4.0 eliminate this problem.)

SpanBox Flow vs. Instrument Flow:

For a SpanBox to work properly, there must be more gas coming out of the SpanBox than the analyzer that is being calibrated is pulling in. If this is not true, then the accuracy of the initial calibration will be compromised.

Best Practice:

Confirm Instrument Flows is less than the SpanBox Flow at the interval required by your company.

Hardware Failure:

Lastly, there could be something wrong with your analyzer. A drifting H2 regulator, contaminated flow systems or low flows to the detector may cause drift failures. These can be some of the hardest to track down (unless you are using a phx21!).

If your phx21 is malfunctioning, just head on over to the Customer Portal under the support section of our website and report an issue. We will be able to tell from the Log file exactly what changed even if we can’t reproduce it, preventing future lost time due to drifts.

Best Practice:

Report drift failures immediately on the LDARtools Customer Portal.

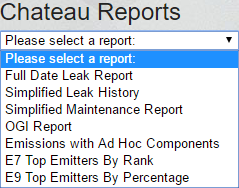

We’ve also added 16 walkthrough videos that demonstrate the ways you can use Chateau to make your LDAR program better. Here’s one of the videos as a preview:

We’ve also added 16 walkthrough videos that demonstrate the ways you can use Chateau to make your LDAR program better. Here’s one of the videos as a preview:

Jeremy Childers officially signed on to join Team LDARtools last year after a brief contractual stint. He’s helped our in-house developers support and create new features for our software products.

Jeremy Childers officially signed on to join Team LDARtools last year after a brief contractual stint. He’s helped our in-house developers support and create new features for our software products. In a world where almost everyone has a consent decree that mandates analyzer drift checks, it is important that we understand and work to prevent any failures. Regardless of which analyzer is being used, here are some quick things to look for in order of frequency:

In a world where almost everyone has a consent decree that mandates analyzer drift checks, it is important that we understand and work to prevent any failures. Regardless of which analyzer is being used, here are some quick things to look for in order of frequency:

Behind the Shades of LDAR Gra/ey Areas Report is a document magician working remotely from Denver, Colorado. Sarah Nisbet, solo super mom and former kindergarten teacher, now completes special projects for the LDAR Think Tank.

Behind the Shades of LDAR Gra/ey Areas Report is a document magician working remotely from Denver, Colorado. Sarah Nisbet, solo super mom and former kindergarten teacher, now completes special projects for the LDAR Think Tank.

But… as good as we are, it is still a remarkable achievement- one that we want to celebrate with everyone who helped to make it happen.

But… as good as we are, it is still a remarkable achievement- one that we want to celebrate with everyone who helped to make it happen. Where can I get OS 1.7.6 ?

Where can I get OS 1.7.6 ? Scott Mortimer is one of the newest members of the LDARtools family.

Scott Mortimer is one of the newest members of the LDARtools family.