Extension probes allow you to get to those components that would normally be difficult to monitor. They can make your life easier, but some questions still linger about this useful tool and the answers are often out of reach.

Thankfully, the experts here at LDARtools are just at the workshop or at their desks designing the next game changer in the LDAR industry. We’ve also asked one of our colleagues at Sage Environmental Consulting to help us. Here are the most common questions about extension probes answered:

Why use an extension probe?

There are many reasons, each of which involves monitoring a component without getting close to it. Some include:

- The component is just out of reach.

- The component is in a confined space.

- You are in an area with a lot of obstructions.

- The component is in an extremely hot area.

- The building has a high background.

Why is it seen as a best practice not to use extension probe?

There is a time and place for everything. Unfortunately, there was a period during which a few people decided that the place for extension probes was on ALL DTMs and the time was ALL the time. Furthermore, early extension probes were just long sticks of stainless steel tubing.

People started asking, “How well can you monitor the top of a flange 20′ in the air with a swaying 1/4″ stick of tubing?” The answer is easy: you can’t.

Thankfully, those days are gone. It’s now a safety best practice to use an extension probe—for select components—if you’re properly using a well-designed extension probe.

When should I not use an extension probes?

While handy, you shouldn’t always rely on an extension probe. Here are the instances when having a longer reach is not advisable:

- When you are on a ladder! Extension probes and ladders don’t mix. Please don’t try.

- When you don’t know the component’s response time.

- When you can’t control the extension probe.

- When you can’t actually monitor the entire emission seam. That means the TOP.

- But most importantly, don’t use an extension probe if you wouldn’t use it in front of a very very tall, dark-haired gentleman from the EPA.

What about antenna-style extension probes?

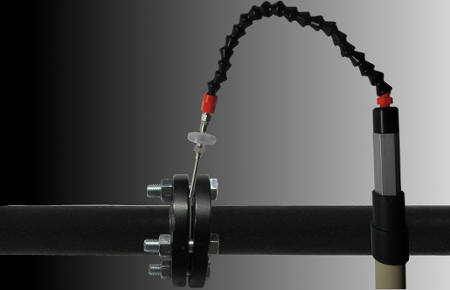

Antenna-style extension probes illustrate the challenge of extension probe monitoring: you don’t just need a probe that is longer or one that can reach farther. You need an apparatus that can, literally, reach around, over, or under the component you are trying to monitor. The point is not to get the probe tip further away from yourself; the point is to be able to position the probe tip along each point of the leak interface. Standard antenna-style probes reach out—but not around.

What are the common pitfalls to avoid when using extension probes?

I asked this very question to Bronson Pate, of Sage Environmental Consulting, recently. He said a common audit finding, in regards to extension probes, is improper response time testing. It’s important (and Method 21 requires) to purge with Zero gas between each response time test. Bronson also pointed out that the best extension probe designs have flexible, articulating tips so you can actually monitor the top of overhead components.

Leave a Reply

Want to join the discussion?Feel free to contribute!