LDARtools is proud to present The LDARtools Customer of the Month Award to Mike Clausewitz & Flint Hills Resources.

At LDARtools one of our core values is “1% Investment Each Day Toward Best”. We strive to invest 1% of everything each day in driving our processes, our products and our relationships from good to better to best.”

As part of our drive toward “Best” we need the help of our customers to provided real world testing and feedback. For their continued assistance in helping us strive for that goal, we present the August 2016 Customer of the Month Award:

In recognition of Mike Clausewitz and the staff of Flint Hills Resources in Corpus Christi for their eagerness and thoroughness when testing new LDARtools software products.

Please join us in thanking them for helping us invest toward best.

Chateau: An LDAR Database Management Program for Today and Tomorrow

Chateau: An LDAR Database Management Program for Today and Tomorrow The Gra/ey Areas of LDAR

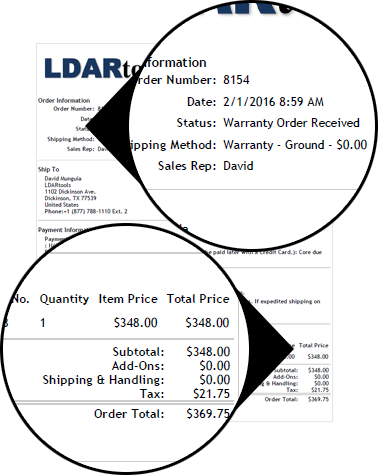

The Gra/ey Areas of LDAR Audit Time with LDARtools

Audit Time with LDARtools