(This blog is based on a joint presentation given by Alan Mata and me at the recent ISA LDAR Symposium held in New Orleans, La.)

As a result of specific, recent events, the intrinsic safety of the fleet of VOC analyzers in use at many sites may be at risk. For several years, expense and logistical difficulty associated with maintenance and repairs on LDAR analyzers has led many companies to seek out and develop alternatives to the discipline with utilizing certified, factory repair facilities.

Uncertified, third-party repair operations started. At the same time, some contractors have developed their own in-house repair processes. The obvious benefits were lower costs for parts, labor and shipping. Unfortunately, the inevitable result has been to compromise the intrinsic safety of the analyzers subject to these “bootleg” repairs.

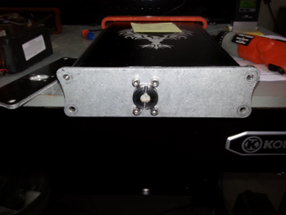

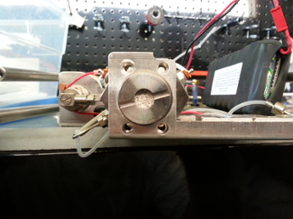

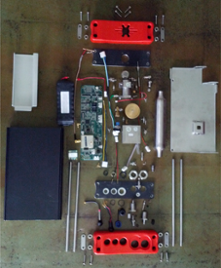

Consider the case of just one of the VOC analyzers on the market today, the phx21: almost 200 separate parts, more than 60 gas/vapor connections and more than 30 electrical connections. When assembled at the LDARtools factory, the instrument is subjected to 240 quality control steps.

Hydrogen molecules have two, very important characteristics. They are very small and they are very combustible. This makes the gas/vapor connections important (they are meant to keep the hydrogen where it belongs). The electrical connections are just as important (they are meant to prevent a ignition of the fugitive hydrogen or other molecules).

Hydrogen where it doesn’t belong exposed to an ignition that shouldn’t be there is a recipe for an LDAR catastrophe.

Hence, 240 quality control steps.

ANYONE performing an unauthorized repair on an analyzer such as this one is likely ignoring a critical, quality and safety perspective: which of the connection(s) has been compromised and which of the quality control steps is required to identify it?

When this question doesn’t get asked(and answered correctly!), very bad things can happen. Technicians are at risk. We will consider those risks in our next post.

Now for something a little more light hearted. Our last post contained a picture of the new pond that was under construction. It’s done and we thought we would have a little fun… See the video below. NOTICE: There is nothing intrinsically safe about what you are about to see.

[youtube https://www.youtube.com/watch?v=maHQQ4se6RE]