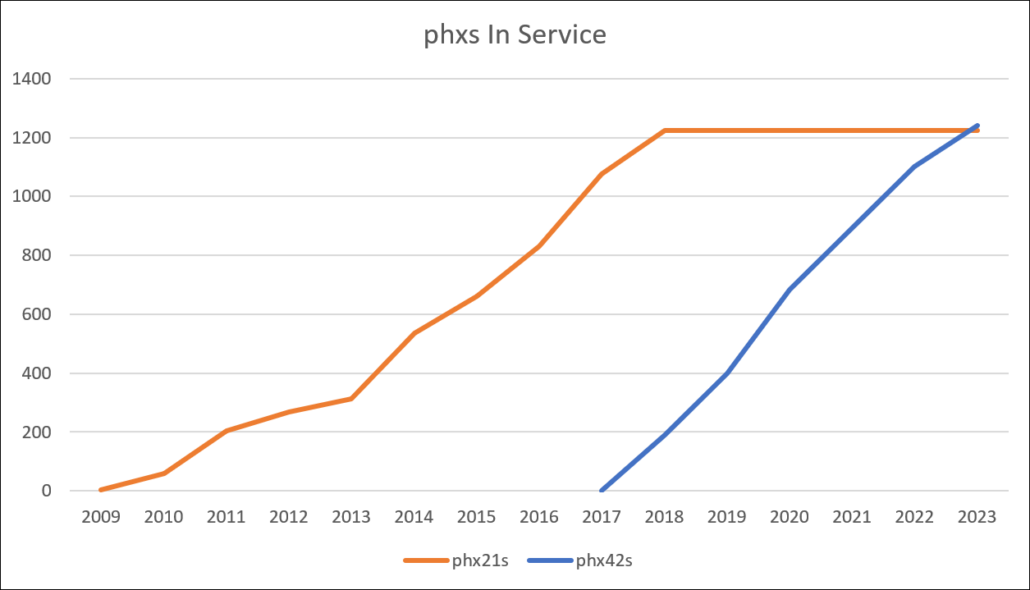

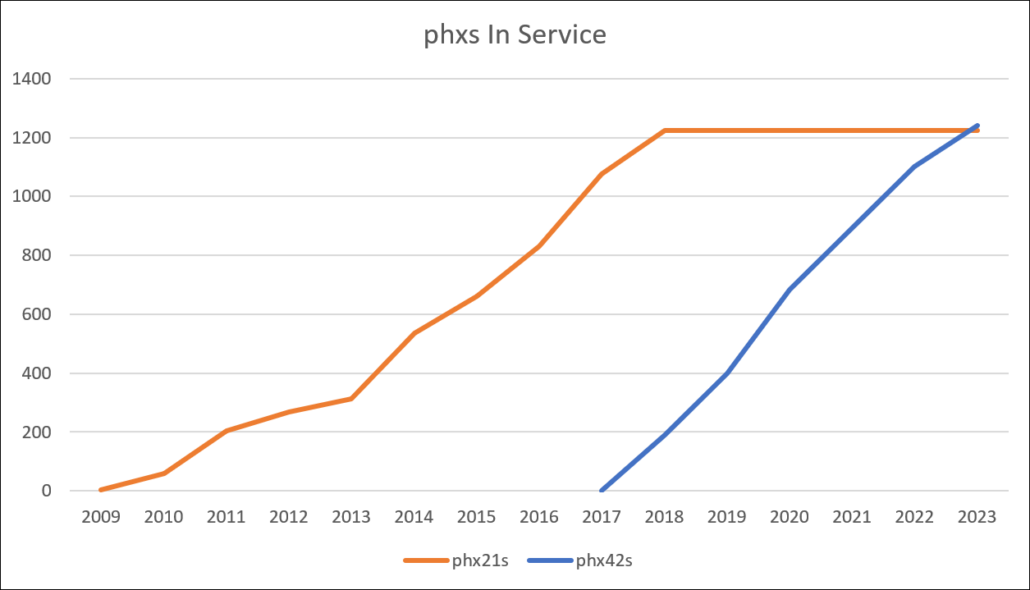

On November 21, 2023, we shipped the 1,226th phx42 FID analyzer, also commonly known as a Toxic Vapor Analyzer or TVA*, surpassing the total number of phx21s (1,225) sold during its lifetime. As of November 30, 2023, we have shipped 1,242 phx42s.

*This is a misnomer, but also a term the industry has accepted to describe portable FIDs.

Amazingly, it took us 108 months to sell those phx21s, and only 69 months to sell the same number of our newest model.

Needless to say, we are proud of this accomplishment and grateful to our customers for making our phx line the premier portable VOC analyzer in the world.

We also want to take a moment to recognize the extraordinary work of the team that designed, built, refined, and, now, repairs the phx42s. I know they are all delighted to be making such an important contribution to the LDAR industry.

And, most of all, everyone recognizes it is Jeremy Bolinger who deserves the lion’s share of the credit, which is why we joke (not really!) each phx42 has been handcrafted by Jeremy!

The BEST news is that as we make this announcement, 99% of all of the phx42s we have ever sold are IN THE FIELD, doing what they were meant to do: LDAR. That’s the important part. Maybe we will have a Brownie Celebration, someday, soon.