For companies still managing their LDAR programs on local servers, Excel, or even paper logs, transitioning to a web-based LDAR database can be a game changer. Imagine the convenience of accessing all your data anytime, anywhere, through a simple internet connection. No more digging through filing cabinets or spreadsheets. Now, all your regulatory and maintenance data is right at your fingertips, with just a few clicks.

Key Benefits:

1. Anywhere Access with an Online LDAR Database

Manage every aspect of your LDAR database from any device connected to the internet. Whether you’re in the office, at home, or on the road, all your essential data is instantly available. This eliminates the constraints of paper records and manual input, allowing you to focus on optimizing your leak detection efforts.

2. Daily Alerts Tailored to Your Needs

Stay proactive with daily email alerts that keep you informed on key metrics, leaks, maintenance requirements, and other critical data. This feature ensures you’re never caught off guard by compliance deadlines or missed repairs, allowing you to stay ahead of regulatory demands.

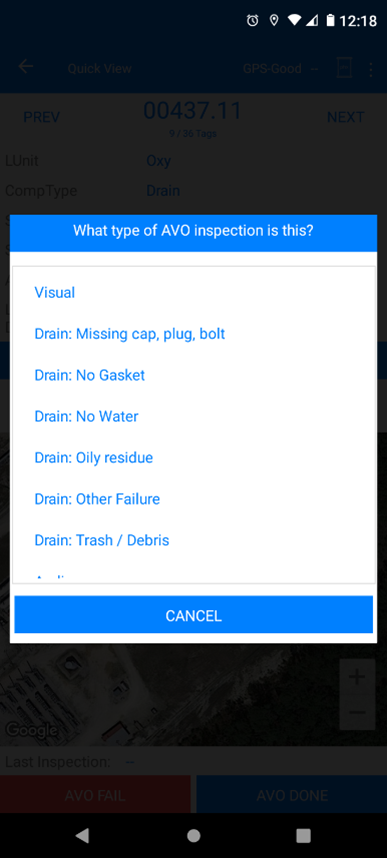

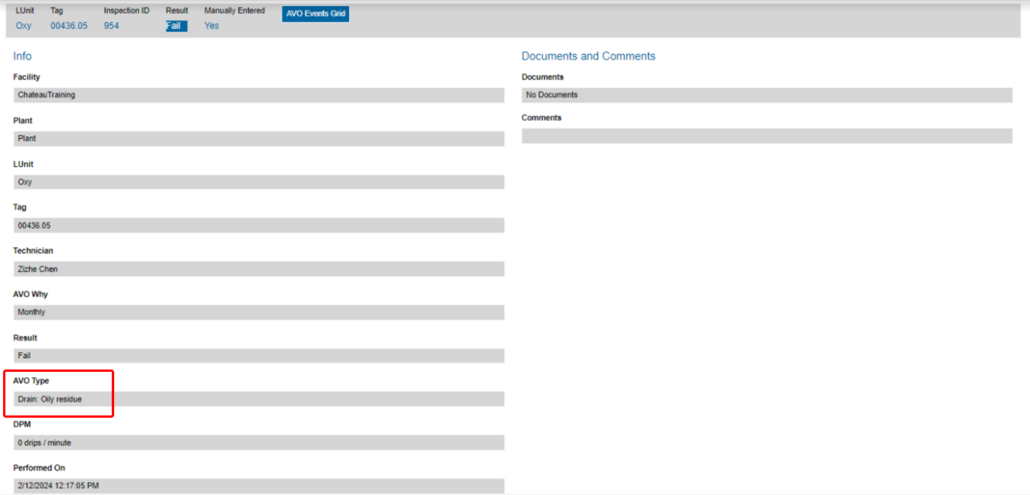

3. Remote Data Access for Field Technicians

Empower your field technicians with the ability to check in and check out data via Wi-Fi, no matter where they are in the world. This functionality enhances real-time communication and collaboration between on-site teams and office-based staff, minimizing delays in addressing leaks and submitting reports. Starlink makes this even more impressive when using a web-based LDAR database.

4. Comprehensive Compliance Management

Managing regulatory and permit requirements becomes seamless with a web-based system. Keep track of all necessary documentation, monitoring, and reporting processes to ensure full compliance with local, state, and federal regulations. This centralized system reduces the risk of errors which often arise from manual processes.

5. Customizable Reports with Database Software

Generate a wide range of reports, including a Full Leak History Report, with just a few clicks. This saves time and provides comprehensive insights for audits, compliance reviews, and internal assessments. Customizable reports ensure you get the data you need in the preferred format.

Moving from a classic database to a web-based LDAR database allows your organization to streamline operations, improve accuracy, and enhance collaboration across teams. It’s a forward-thinking approach that simplifies compliance while giving you greater control over your data. Say goodbye to paper clutter and manual errors. Welcome the future of LDAR management with a powerful, cloud-based solution!