Due to winter weather in the Houston area on Tuesday 1/16 and Wednesday 1/17, please call 877-788-1110 x 6 before coming to the office to pick up or drop off.

Price increases are not surprising.

In spite of rising prices for virtually everything we need, we have continued to invest in making our products the most innovative and valuable tools for the LDAR industry. The time to reckon with those costs has come.

Effective January 1, 2024, there will be a less than 10% increase on:

- phx42

- SpanBox (all models)

- Fill adapter

Price increases triggered by specific vendor costs will be passed on as we have in the past If you have any questions, please feel free to contact sales@ldartools.com.

Through it all, we appreciate your business.

Monday, December 25, 2023

Warehouse Closed

Tuesday, December 26, 2023

Warehouse open 8 a.m. – 5 p.m.

All normal shipping operations resume

Limited staff, Support responses may be delayed

Monday, January 1, 2023

Warehouse Closed

Tuesday, January 2, 2023

Warehouse open 8 a.m. – 5 p.m.

All normal shipping operations resume

Have a blessed and safe holiday.

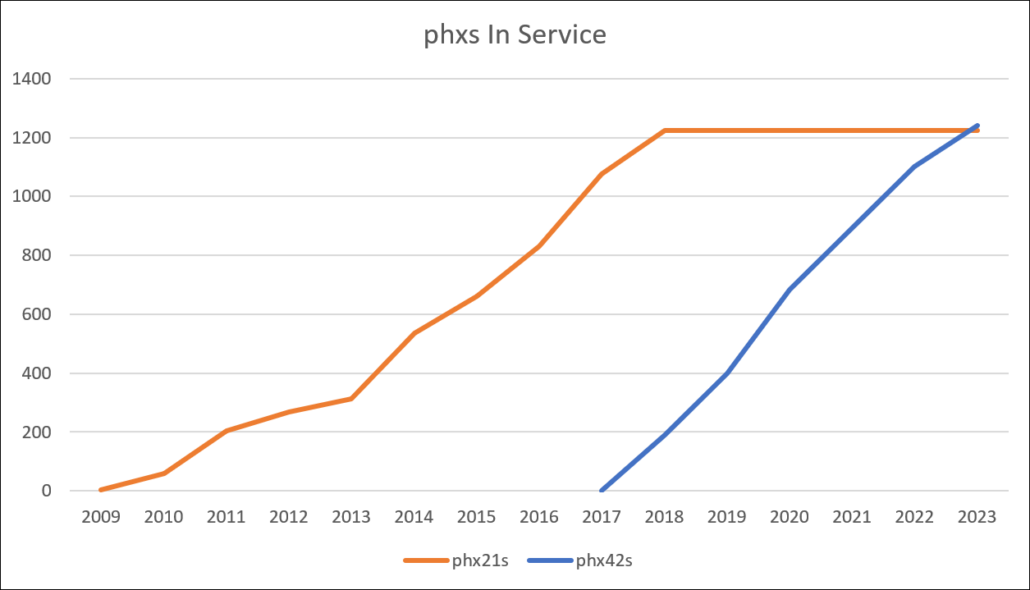

On November 21, 2023, we shipped the 1,226th phx42, surpassing the total number of phx21s (1,225) sold during its lifetime. As of November 30, 2023, we have shipped 1,242 phx42s.

Amazingly, it took us 108 months to sell those phx21s, and only 69 months to sell the same number of our newest model.

Needless to say, we are proud of this accomplishment and grateful to our customers for making our phx line the premier portable VOC analyzer in the world.

We also want to take a moment to recognize the extraordinary work of the team that designed, built, refined, and, now, repairs the phx42s. I know they are all delighted to be making such an important contribution to the LDAR industry.

And, most of all, everyone recognizes it is Jeremy Bolinger who deserves the lion’s share of the credit, which is why we joke (not really!) each phx42 has been handcrafted by Jeremy!

The BEST news is that as we make this announcement, 99% of all of the phx42s we have ever sold are IN THE FIELD, doing what they were meant to do: LDAR. That’s the important part. Maybe we will have a Brownie Celebration, someday, soon.

Effective January 1, 2024 we will be increasing the price of an annual Cal5.0 license from $1,320 to $1,500 per year. This is only the second price increase we have had in the last 10 years.

The reason for this increase is, of course, the general pressure on pricing and expenses we are all experiencing. Additionally, it recognizes the extraordinary value of having our cloud-based database, Chateau, available for housing the data along with adding Chateau’s industry-standard QC tools.

As a part of this process, we are proud to announce that Cal5.0 users, who are using Chateau to store and manage their calibration data, will have access to the full functionality of Chateau’s auditing, alert and porch tracking features for the most important aspects of their calibration data.

The following chart will detail the specific Calibration Audits currently available to Chateau users.

Please note that, with each audit, you can trigger an audit-specific, same-day email alert to an unlimited number of email addresses to any responsible party.

| 10 Days since On-Site Analyzer Cal | Any active analyzer and has not been calibrated in 10 or more days. |

| 72 Hours Since Last Daily Calibration | It has been 72 hours since the most recent Daily Calibration record on ANY analyzer. |

| 80 Days since Analyzer PreCal | Any active analyzer that has not been precision calibrated in 80 days or more. |

| Cylinders expiring In <30 Days | Any cylinder expiring in less than 30 days. |

| Any Failed Drift | Analyzer was calibrated and passed daily calibration, and then later that day failed any Drift Assessment. |

| No Noon Drift | Analyzer was calibrated and passed Daily Calibration, and no Drift Assessment was performed with 6 hours of that calibration time. |

| No Passing Second (EOD) Drift | Analyzer was calibrated and passed Daily Calibration, a passing Noon Drift was performed, and no Drift Assessment was performed within 6 hours of the noon drift for that day. |

| Inspections in last 30 Days with no Daily Calibration | This Audit only available for programs where Chateau is being used to manage the LDAR inspection and compliance program. |

| Inspections in last 30 Days with no Precision Calibration | This Audit only available for programs where Chateau is being used to manage the LDAR inspection and compliance program. |

| Inspections without passing drifts | This Audit only available for programs where Chateau is being used to manage the LDAR inspection and compliance program. |

As we make this announcement, we would like to take this opportunity to encourage all of our CalX.x customers who are using LTI Desktop to manage calibration records (and no other LTI software) to begin making plans to transition to Chateau as the state-of-the-art medium for storing their calibration data.

We are thrilled to announce there are more than 2,300 phx21 and phx42 analyzers worldwide. This significant milestone fills us with immense pride, and we are eager to share this momentous achievement with you. Checkout the image below to see where in the world we have sold our portable FIDs

The hustle and bustle of the modern workplace often leaves us longing for new ways to kickstart our day with energy and focus. At the LDARtools office, a refreshing cold plunge has been the top choice. In the pursuit of workplace wellness, a morning ice bath has been an unexpected yet highly effective solution in jumpstarting the day.

Benefits of Cold Plunges at Work:

1. Enhanced alertness: The shock of cold water triggers your body’s natural response to stress, releasing adrenaline and boosting alertness. This heightened awareness can help you tackle tasks with renewed focus.

2. Improved Circulation: Cold water immersion constricts blood vessels, which can improve circulation and help reduce inflammation. Better circulation means your body can efficiently transport nutrients and oxygen to where they’re needed most.

3. Elevated Mood: Cold exposure prompts the release of endorphins – those “feel-good” hormones that can uplift your mood and reduce stress levels. Starting your day positively sets the tone for a productive workday.

4. Stress Reduction: Plunging into cold water triggers the body’s parasympathetic nervous system, promoting relaxation and reducing stress. What better way to shake off work-related worries(not that we have any:-)?

In a world where environmental concerns have taken center stage, innovative solutions are the need of the hour. South Korean distributor YNJ recently stepped into the limelight as a key participant in the 44th International Exhibition on Environmental Technology and Green Energy, popularly known as ENVEX. This prestigious event showcased the power of collaboration, bringing together 250 exhibitors from 20 countries, with an expected influx of 30,000 visitors, including 500 overseas buyers.

**A Global Platform for Environmental Technology and Green Energy**

ENVEX, a longstanding beacon of green innovation, held its 44th annual exhibition, setting the stage for industry leaders, innovators, and stakeholders to converge and discuss pressing environmental challenges. Hosted on an international scale, the event attracted participants from diverse corners of the globe, all committed to presenting solutions that could shape a sustainable future.

**YNJ’s Standout Presence**

At the heart of ENVEX, YNJ stood as a prominent representative of South Korea’s dedication to environmental stewardship. As a leading distributor for LDARtools, YNJ showcased an array of cutting-edge solutions with a special focus on the phx42 and enhanced ZOM features. YNJ’s booth radiated innovation and ingenuity.

**A Sustainable Future Beckons**

As the curtains fell on the 44th ENVEX exhibition, it left behind a trail of inspiration and hope. The event underscored the importance of collaboration and innovation in tackling global environmental challenges. YNJ’s notable presence served as a testament to the power of businesses driving change by offering sustainable solutions. As technology advances and global connectivity grows, the potential to create a greener future becomes increasingly tangible. In the end, the 44th International Exhibition on Environmental Technology and Green Energy was not just an event; it was a rallying cry for a world that demands sustainable solutions. It showcased that when businesses, visionaries, and innovators unite, the path to a cleaner, more sustainable future becomes clearer than ever before.

Chateau Features Fixed or Improved:

Attempts:

- Switched order of Inspection and Attempts processing in Chateau Mobile to automatically resolve closed Leaks with Attempt and passing Inspection not working when performed in the same session.

Porches:

- MOC Porch processing improved to allow Users to approve multiple edits to a single Component simultaneously.

Leaks:

- New option for frequency of Leak Alerts: ‘Immediately upon Check-in.’ Select this option to immediately send an email when a Leak has been opened in Chateau, either from a manually added failing Inspection or a Leak processed in from Chateau Mobile.

- Reporting emissions on DORs is now supported. When a DOR is opened, there is now an option to select the Emission Model that should be used for this DOR. On the DOR details and DOR grids, a Total Emissions and a Projected Emissions column has been added to report this. Projected emissions will be calculated using the Estimated Repair date from each DOR.

- Reporting projected emissions for Shutdowns is now supported. For each shutdown, the projected emissions for all DORs assigned to that Shutdown will be reported to the Shutdowns grid. Projected emissions will be calculated using the Estimated Repair date from each DOR.

- First Attempt, First Retest, and Final Resolution due dates are now converted to the facility time zone on the leaks grid.

Tours:

- Tour Details screen now supports Spanish language.

- The “Move to Another Tour” prompt is now correctly sized to display the buttons without scrolling.

Field Events:

- Added new Component Prompts module to display tailored messages to the Technician in Chateau Mobile based on component properties. Use the query builder to specify which Components you want a message to be displayed in Chateau Mobile to the technician when they first open that Component in the handheld, then type out the message you want them to see.

Reports:

- Type was added as a parameter for the Simplified Leak History, Inspection History, DOR Summary Agency, DRO Summary, and Periodic Inspection Summary reports.

Help:

- When submitting a support issue from Chateau, the urgency can now be selected.

User Experience:

- Additional logging was added throughout Chateau to help resolve issues and crashes.

- Added better support for multiple API instances for faster checkouts.

Component:

- Previously if a Rule did not have an M21 or AVO Frequency for a Component, that Rule did not show in the Tag View/Rules tab. This has been resolved, and now all Rules that are or have been assigned to the Component appear in the Tag View Rules Tab.

- When saving a Component edit or new Component, the ‘Run Rules after Saving’ prompt is now unchecked by default for faster save times. If you would like the rules to run on your changes immediately, then just check the box before clicking save.

Chateau Mobile Features Added or Improved:

Components:

- Resolved an error when adding a component from scratch back-to-back using the Add component from scratch option in the Main Menu.

- Shortened dialog prompt on the Archer 3 for when saving TUx Profile changes so the Android navigational buttons do not prevent the Technician from tapping save.

User Experience:

- Additional logging was added to help troubleshoot app crashes and freezes.

Field Events:

- Added new Component Prompts module to display messages when a component is opened in the tour.

Tours:

- Resolved an occasional issue of negative numbers showing for the number of completed inspections.

We wanted to update our longtime phx21 users on the status of our phx21 product and our immediate and near-term plans.

We announced the End of Life for phx21 in March 2017. At that time, we projected that we would be able to support phx21s until April 1, 2022.

We have exceeded that timeline by 15 months.

It is becoming more and more difficult to source several of the critical components. Of the ten critical parts, six (6) are beyond our capacity to source, provide or design/certify alternatives. These are the battery, charger, Bluetooth, mainboard, solenoid and high-pressure sensor.

We have limited supplies of some of these parts. Others are completely exhausted.

If and when one of your units needs one of these parts, and such parts are no longer available, it will be unrepairable.

Within these limitations, we will continue to provide the best repair and support services for your ph21 units.

Of course, if and when you are prepared to upgrade to the new phx42, we hope you will contact sales@ldartools.com.

LDARtools

1102 Dickinson Ave.

Dickinson, Texas 77539

USA

Telephone: +1 (877) 788-1110

Fax: +1 (866) 385-9142

Hours of Operation

Mo-Th: 8:00AM – 5:00PM

Fr: 8:00AM – 3:00PM

After Hours: By Appointment

© 2024 LDARtools. All rights reserved.