Due to winter weather in the Houston area, our home office in Dickinson will be closed Wednesday morning (1/22) until 12:00 PM.

Support responses might also be delayed.

Please call 877-788-1110 x 6 before coming to the office to pick up or drop off.

Due to winter weather in the Houston area, our home office in Dickinson will be closed Wednesday morning (1/22) until 12:00 PM.

Support responses might also be delayed.

Please call 877-788-1110 x 6 before coming to the office to pick up or drop off.

Due to winter weather in the Houston area, our home office in Dickinson will be closed Tuesday 1/21 and may also be closed Wednesday 1/22.

Support responses might also be delayed.

Please call 877-788-1110 x 6 before coming to the office to pick up or drop off.

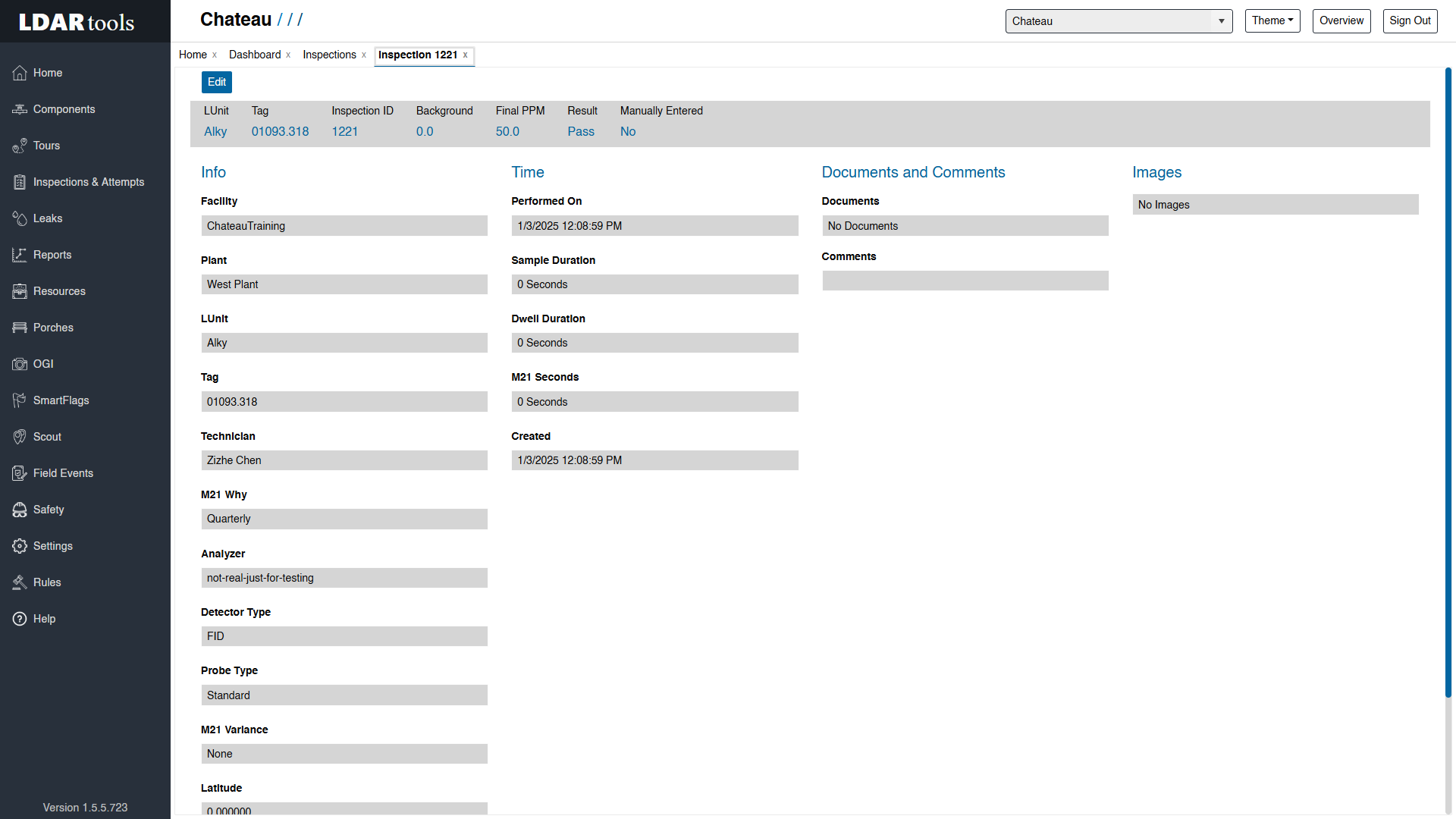

Managing inspections can be a daunting task, especially when juggling multiple inspection types such as M21, OGI, AVO, and Cooling Tower checks. Each inspection requires unique tools, methodologies, and documentation, making it challenging to stay organized while ensuring compliance. Fortunately, with Chateau, scheduling and managing these inspections in a cloud-based database has never been easier or more efficient.

Why Choose Chateau for Your Inspections?

Chateau isn’t just a database; it’s a powerful cloud-based database specifically designed to simplify inspection management. Trusted by industry professionals, it offers unmatched reliability, precision, and adaptability. Whether you’re overseeing environmental compliance, safety protocols, or operational standards, Chateau provides an all-in-one platform that ensures every inspection type is executed seamlessly.

Key Benefits:

Scheduling M21 Inspections

M21 inspections, performed under EPA regulations, involve using a flame ionization detector (FID)—commonly known as a Toxic Vapor Analyzer or TVA—or other approved instruments to measure emissions from equipment components. With a cloud-based database platform such as Chateau, scheduling and tracking M21 inspections becomes straightforward.

Chateau’s intuitive interface ensures each M21 inspection is completed on time while maintaining precise record-keeping for regulatory submissions.

Managing OGI Inspections

OGI (Optical Gas Imaging) inspections require advanced infrared technology to detect gas leaks. These inspections are critical for environmental safety and compliance under regulatory frameworks like NSPS OOOOa.

With Chateau’s robust capabilities, OGI inspections are conducted efficiently while ensuring that all findings are meticulously documented.

Simplify AVO Inspections

Audio, Visual, and Olfactory (AVO) inspections are often the first line of defense in identifying leaks or equipment malfunctions. Unlike instrument-based inspections, AVO relies on a technician’s senses to detect irregularities.

By bringing AVO inspections into a cloud-based database platform like Chateau, businesses gain a streamlined way to combine their sensory-based findings with other data-driven inspections.

Optimize Cooling Tower Inspections

Cooling Tower inspections play a vital role in maintaining energy efficiency. With Chateau, tracking these often-complex inspections becomes hassle-free.

Chateau allows teams to safeguard cooling tower performance while ensuring regulatory compliance standards are met.

Why a Cloud-based Solution Benefits Your Inspections

Unlike traditional, on-premise systems, a cloud-based database platform like Chateau offers unparalleled advantages for inspection management.

Streamline Compliance and Inspections with Chateau

From regulatory obligations to operational efficiencies, inspections are a critical aspect of any industrial operation. With Chateau, you can ensure every M21, OGI, AVO, and Cooling Tower inspection is scheduled, managed, and documented to perfection in a cloud-based database.

Don’t leave your inspection processes to chance. Empower your team with a solution trusted by industry professionals worldwide. Experience how Chateau can revolutionize your inspection management system.

Effective January 1, 2025, we will no longer repair phx21s, or make them available for rent. If you have a phx21 requiring repairs, please request an RMA by 12/31/24, and we will repair it if the required parts are available.

For now, we will continue to support phx21 troubleshooting through hardware issues, and supply the following parts for level 1 repairs while supplies last:

| LPN | Part Name |

| 766 | Glow Plug |

| 1016 | Probe Quick Connect |

| 1157 | Thermocouple |

| 1163 | Pump Assembly |

| 1541 | Batt. Connection Harness |

Since the phx21 made its debut in 2008, LDARtools has worked to produce high-quality products and services for our customers. With 1,219 phx21s and 17 Brownie Celebrations (no machines in for repair) later, we say a fond farewell as the era of the phx21 draws to a close.

We look forward to our continued support of your LDAR programs with the phx42 and Chateau.

Please contact sales@ldartools.com if you need assistance with a quote.

The achievement of 1,000 users is not just a number; it’s a reflection of the trust and satisfaction of our community.

Our users come from various industries, each utilizing Chateau to streamline processes, boost productivity, and achieve their goals. It is this diversity and the success stories of our users that drive us to keep pushing boundaries and setting new standards.

Chateau’s growth is not merely about numbers; it’s about the stories and the successes of our users. With a focus on delivering the best possible service, our platform has evolved significantly over time. Each update and feature has been carefully crafted to enhance user experience, ensuring that Chateau remains at the forefront of the industry. We’ve listened to user feedback and made continuous improvements, resulting in a platform that is both user-friendly and highly functional.

Click here to receive celebration stickers!

You can also email sales@ldartools.com with the following information:

Thank you for being part of the Chateau community. Here’s to your continued success—and to reaching new milestones together!

Leak Detection and Repair (LDAR) programs are essential for managing and mitigating fugitive emissions in industrial environments. Furthermore, by leveraging advanced technologies, such as the phx42 FID analyzer, SpanBox5 calibration system, and Chateau database software, you can streamline the detection, quantification, and reporting of leaks to ensure safety and environmental compliance.

Here’s a step-by-step guide to creating an effective LDAR program using these tools.

The phx42 Flame Ionization Detector (FID) analyzer, also commonly known as Toxic Vapor Analyzer or TVA*, is at the heart of your LDAR program, designed for accurate detection of hydrocarbons to aid with environmental compliance. Begin by:

*This is a misnomer, but also a term the industry has accepted to describe portable FIDs.

A quality analyzer is not enough, however. Additionally, you will need an efficient calibration system for your analyzers. The SpanBox5 FID calibration system is an innovative tool for automating the calibration and verification process of the phx42. To integrate the SpanBox5:

Lastly, you will need a central to house all of this information. LDARtools’ Chateau LDAR database software serves as this hub for managing all the data collected from your LDAR program, and is the final step in meeting the highest standards of environmental management. Here is how to use it:

Creating an LDAR program with the phx42 FID analyzer, SpanBox5 calibration system, and Chateau database software offers a robust, integrated approach to managing fugitive emissions to ensure environmental compliance. By following these steps, you can ensure your program is efficient, compliant, and capable of detecting leaks accurately and responding promptly.

Negative Flameout Values

A recent firmware update addressed the representation of negative values in the phx42 FID analyzer, also commonly known as a Toxic Vapor Analyzer or TVA*. Negative values always indicate a flame-out condition, where the FID is not detecting any VOCs due to a lack of ignition. The firmware update ensures these negative values are represented in a specific manner, avoiding confusion and ensuring accurate readings. The specific negative value displayed indicates the reason the phx42 is not ignited.

*This is a misnomer, but also a term the industry has accepted to describe portable FIDs.

| Reading | Error Message |

|---|---|

| -40 | “Pump at max power for too long, report the issue.” |

| -41 | “Probe Flow is blocked. Check Probe/ Change Filter.” |

| -42 | “Feels like you just removed my filter. Please give me a fresh filter so we can get back to work.” |

| -45 | “Looks like we just found a high PPM leak. Wait 30 seconds and reignite me. (Chamber overtemp)” |

| -46 | “Trying to ignite! If 3rd attempt fails, report the issue.” |

Contamination During Calibration

When any analyzer is calibrated, any contamination from previous days leaks that burns off during the day can cause the readings to shift slightly. This is a linear shift across the scale. That is to say, 1 ppm (parts per million) of contamination is burned off, it will reduce ambient by 1 ppm as well as 10,000 ppm.

Previously, if the phx21 detected a value below the zero-calibrated level, it would enter a pattern of alternating 0.0 and 0.1 readings. This pattern was implemented to avoid displaying a negative value, which is not possible in practical scenarios as readings cannot be less than 0 ppm. This would result in lower readings throughout the calibration scale. All portable FIDs at the time could experience this drift, resulting in lower readings throughout the day as well as during drifts.

Calibration Adjustments to the phx42

When the phx42 is calibrated under contaminated conditions and then later burned off, causing the ppm level to drop below 0 for more than 1 minute, the calibration table is edited in real-time. This adjustment is crucial for maintaining accuracy, as it corrects all the calibration points for any leftover VOCs which may have affected the calibration process and are no longer impacting the machine.

Conditions must be met for this adjustment to take place. The firmware monitors multiple conditions to ensure the machine is ignited and running properly. If a flame out/reignition occurs, the calibration table will revert to the original version to prevent an outside factor, like a probe or filter change, from impacting this feature (the phx42 will shut down during filter or probe changes). If, after reignition, the ppm returns to negative for the required time, adjustments will be made again as appropriate.

Practical Implications

In the older portable FID models—including phx21, TVA1000, and TVA2020—negative drift would cause interruptions, requiring work stoppage, recalibration, drift failures, and rework. The phx42, with its improved firmware, eliminates these issues by ensuring readings never fall into negative territory and that accuracy is maintained.

Conclusion

The phx42 portable FID by LDARtools is an advanced instrument for VOC detection, with sophisticated firmware to handle calibration and negative values efficiently. By continuously improving its firmware, LDARtools ensures the phx42 remains a reliable and accurate tool for environmental monitoring, minimizing the need for manual interventions and providing consistent accuracy.

1102 Dickinson Ave.

Dickinson, Texas 77539

USA

Telephone: +1 (877) 788-1110

Fax: +1 (866) 385-9142

Mo-Th: 8:00AM – 5:00PM

Fr: 8:00AM – 3:00PM

After Hours: By Appointment

© 2026 LDARtools. All rights reserved.