LDARtools will be in Austin, Texas next week for the 4C Environmental Conference to inspire and inform our friends in the LDAR industry.

From Monday, February 16, to Thursday, February 19, we’ll have several booths set up (Booth 42 and 43) to showcase our products and to answer any questions you may have about our offerings. Our very own Erica Gentry, LDARtools’ Sales and Purchasing Manager, will be in attendance to assist you with your LDAR needs.

Rex Moses, LDARtools’ President and CEO, will also be on hand to give three presentations throughout the week on LDAR topics that are absolutely essential to your LDAR program. Check each summary for a sneak peek:

Rex Moses, LDARtools’ President and CEO, will also be on hand to give three presentations throughout the week on LDAR topics that are absolutely essential to your LDAR program. Check each summary for a sneak peek:

Cooling Tower Essentials

Tuesday – February 17, 2015 – 1PM to 5PM

In Cooling Tower Essentials, you will learn about various aspects of the cooling tower monitoring requirements found in MACT CC, including a background of the rule, test methods, how to properly implement the rule, and industry best practices. Furthermore, you will learn about new technologies for cooling tower monitoring from LDARtools.

Mushrooms and Gold: Mining LDAR Data to Ensure Compliance, Quality, and Productivity

Wednesday – February 18, 2015 – 1:30PM to 2:15PM

The typical LDAR program generates hundreds, thousands, or potentially, millions of pieces of data. From PPM records to MOC entries, time/date stamps and GPS coordinates, these data not only enable essential regulatory compliance and reporting. They also paint a vivid image of what was going right and what could have gone better.

The challenge is that critical information can be lost in the overwhelming volume of data and, unfortunately, may not surface until it is too late. Like the mushroom picker in the Yukon who became one of the world’s top gold prospectors, LDAR professionals can learn valuable lessons about where the golden data is and how best to find it.

Auditing Using LDARtools Equipment and Software

Thursday – February 19, 2015 – 8AM to 12PM

The historical focus of LDAR Audits on Compliance issues, to the exclusion of productivity and quality, results in value leaks and broken windows. The old perspective was that productivity was the “contractor’s problem.” But accountability, reliability and discipline are seamless disciplines that have a uniform effect on compliance, productivity and quality. The LDAR Audits of the future will be focused not on “what went wrong,” but on “how well did our system for preventing the deviations (i.e. generating quality) work?”

***

While we have a lot of things going on at the presentation, you definitely HAVE to check out Booth 42 and 43 to see what LDARtools is working on. We have a couple of surprises in store for everybody.

Ready for next week? Double-check the event’s venue information:

Ready for next week? Double-check the event’s venue information:

110 E 2nd Street

Austin, TX 78701

512-474-4777

Hotel Parking

Valet – $35/day

Self-parking – $30/day

Note: 4C Attendees will receive a 10% discount on parking.

Overflow Parking

Transportation

- Super Shuttle – The 4C Environmental Conference has set up airport transportation service through Super Shuttle.

- Austin Cab – 512-478-2222, approximately $25 from Austin Bergstrom Airport to the hotel.

For more information, the 4C Environmental Conference website will have everything you need.

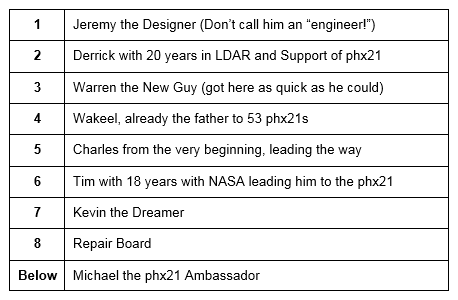

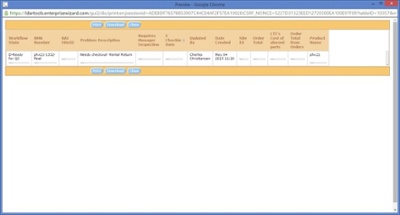

The photo of the phx21 team and the Repair Board (which is actually a monitor that displays our state-of-the-art equipment management software) tell the story: 615 phx21s in the field and not a single one in for repair. The only item displayed is one of our fleet units that has just come back from a rental and was being put through our 7-hour QC process. (You can see this in the insert of the screen itself.)

The photo of the phx21 team and the Repair Board (which is actually a monitor that displays our state-of-the-art equipment management software) tell the story: 615 phx21s in the field and not a single one in for repair. The only item displayed is one of our fleet units that has just come back from a rental and was being put through our 7-hour QC process. (You can see this in the insert of the screen itself.)

The day didn’t start out so hot though. Rain cast a gloomy pall across some parts of Houston (and there was flooding in some areas!). It seem that the weather wasn’t going to cooperate but luckily, by 2 PM, the skies cleared and the soccer game was afoot.

The day didn’t start out so hot though. Rain cast a gloomy pall across some parts of Houston (and there was flooding in some areas!). It seem that the weather wasn’t going to cooperate but luckily, by 2 PM, the skies cleared and the soccer game was afoot. The game was a dramatic 4-4 draw with Sporting Kansas City. It was generally as exciting as all soccer (or futbol) games go. Asked about any highlight that she remembers, Marian says “There was a fight but it didn’t last that long.”

The game was a dramatic 4-4 draw with Sporting Kansas City. It was generally as exciting as all soccer (or futbol) games go. Asked about any highlight that she remembers, Marian says “There was a fight but it didn’t last that long.”

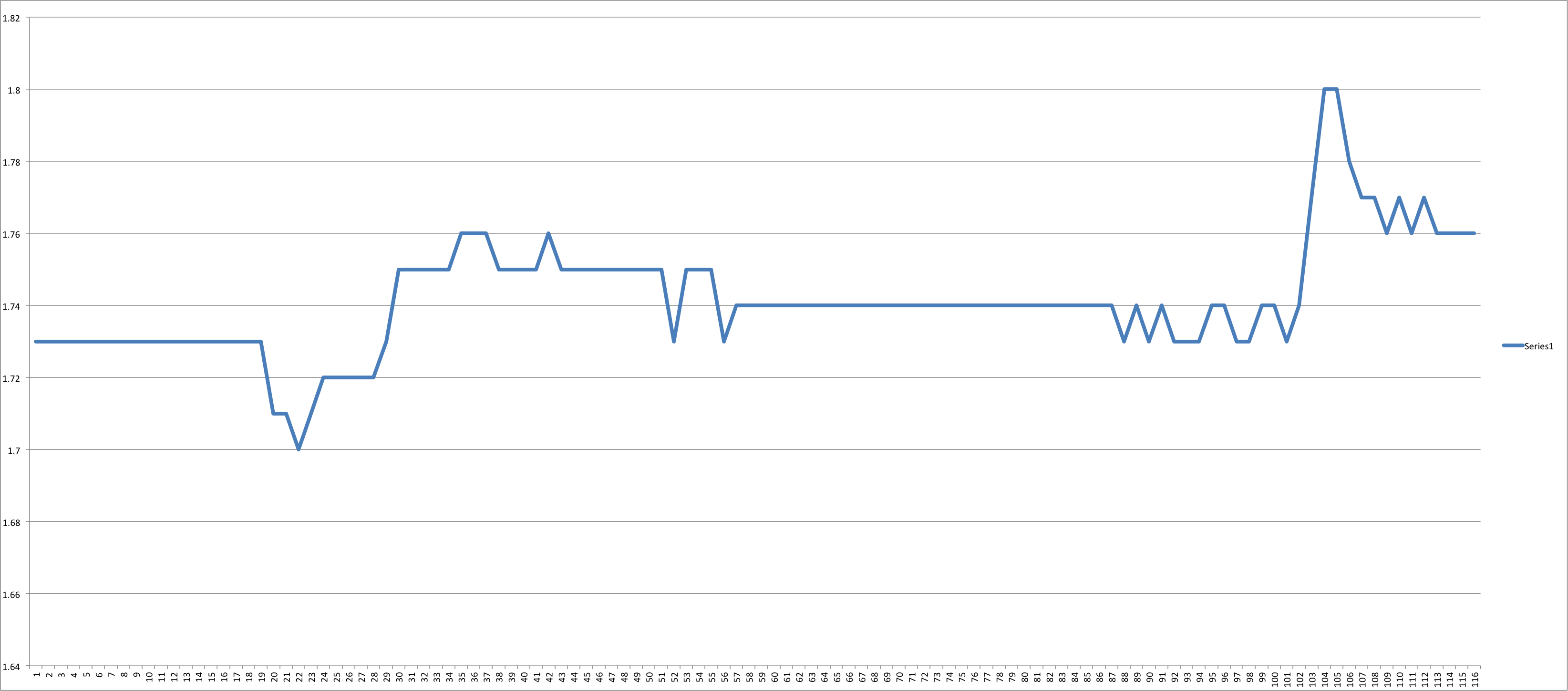

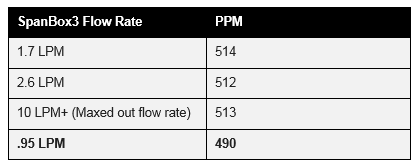

Of course, if the flow rate on the SpanBox is less than the flow rate of the phx21 (.95 LPM) then you can get unpleasant results. That is why the LDAR Think Tank recommends that the flow rate on the SpanBox be set at 2 LPM. This is a one-time setting that takes mere minutes to make and requires no further maintenance.

Of course, if the flow rate on the SpanBox is less than the flow rate of the phx21 (.95 LPM) then you can get unpleasant results. That is why the LDAR Think Tank recommends that the flow rate on the SpanBox be set at 2 LPM. This is a one-time setting that takes mere minutes to make and requires no further maintenance. As our team arrived at the course, the weather was not looking too promising. But we were able to stay dry for most of the tournament. Our team shot a 63 (!)—good enough to avoid being embarrassed but not good enough to win.

As our team arrived at the course, the weather was not looking too promising. But we were able to stay dry for most of the tournament. Our team shot a 63 (!)—good enough to avoid being embarrassed but not good enough to win. From left to right: Rex Moses of LDARtools, Roy Massengale of EnRUD, Erica Gentry of LDARtools, Spring Janke of Styrolution America, and Mike Early of Shell

From left to right: Rex Moses of LDARtools, Roy Massengale of EnRUD, Erica Gentry of LDARtools, Spring Janke of Styrolution America, and Mike Early of Shell From left to right: Marian Regan, Philip Trevino and Chris Ledbetter

From left to right: Marian Regan, Philip Trevino and Chris Ledbetter

The cancerous tumor in Claire’s spinal cord causes damage to the nerves that help control her lower body’s movement. With the Chemotherapy treatments at Texas Children’s Hospital lasting for months, her family has a tough journey ahead of them.

The cancerous tumor in Claire’s spinal cord causes damage to the nerves that help control her lower body’s movement. With the Chemotherapy treatments at Texas Children’s Hospital lasting for months, her family has a tough journey ahead of them. If you would like to donate, please contact Maria Ramos (1-713-412-1314) or LaRisa King (1-832-566-2193).

If you would like to donate, please contact Maria Ramos (1-713-412-1314) or LaRisa King (1-832-566-2193).

Rex Moses, LDARtools’ President and CEO, will also be on hand to give three presentations throughout the week on LDAR topics that are absolutely essential to your LDAR program. Check each summary for a sneak peek:

Rex Moses, LDARtools’ President and CEO, will also be on hand to give three presentations throughout the week on LDAR topics that are absolutely essential to your LDAR program. Check each summary for a sneak peek: Ready for next week? Double-check the event’s venue information:

Ready for next week? Double-check the event’s venue information: