Ethylene oxide (EtO) is a colorless, flammable gas widely used as a sterilizing agent in various industries, including the medical, pharmaceutical, chemical, and agricultural sectors. Due to its potential health risks, the Environmental Protection Agency (EPA) has established strict regulations to limit EtO emissions and maintain air quality. In this blog, we will discuss the key users of EtO, the impact of these regulations on air quality, the importance of using advanced detection methods like the phx42 FID to find leaks, and the necessity of continuing to monitor and enforce these standards.

1. Who Uses Ethylene Oxide and Its Health Risks

EtO is primarily used by several industries:

a. Medical and Pharmaceutical Industries:

EtO is a highly effective sterilizing agent, making it a popular choice for sterilizing medical equipment and pharmaceutical products that cannot withstand high temperatures or moisture. This includes items such as surgical instruments, sutures, catheters, and implantable medical devices.

b. Chemical Industry:

EtO is used as a precursor to produce ethylene glycol, a critical component in the manufacturing of products like antifreeze, polyester fibers, and plastic bottles. It is also used to manufacture other chemicals, such as surfactants, detergents, and adhesives.

c. Agriculture:

In some cases, EtO is used to fumigate and sterilize agricultural products, like spices and grains, to eliminate bacteria, fungi, and pests.

d. Food Packaging:

While less common, EtO may also be used to sterilize certain types of food packaging materials that are sensitive to heat or moisture.

EtO is classified as a carcinogenic substance, with long-term exposure linked to an increased risk of certain types of cancer, including leukemia and lymphomas. Additionally, acute exposure can cause respiratory irritation, headache, dizziness, and other neurological symptoms. Given these potential health impacts, it is crucial to regulate EtO emissions to protect both the environment and public health.

2. EPA Regulations on EtO Emissions

In 2008, the EPA revised the National Emission Standards for Hazardous Air Pollutants (NESHAP) to further limit EtO emissions from industrial sources. The 2008 regulations established stringent control measures for EtO emissions, including requirements for control devices, monitoring, recordkeeping, and reporting.

In response to growing concerns about the potential health risks of EtO exposure, the EPA has continued to strengthen its regulatory framework. In 2016, the EPA’s Integrated Risk Information System (IRIS) program updated its risk assessment for EtO, significantly lowering the acceptable exposure level.

3. The Impact of Regulations on Air Quality

Since the implementation of stricter EPA regulations, there has been a significant decrease in EtO emissions. Monitoring data indicates that facilities subject to NESHAP requirements have achieved substantial emission reductions, resulting in improved air quality in surrounding communities.

In addition to federal regulations, some states have adopted even more stringent standards for EtO emissions. This has led to further reductions in emissions and improvements in air quality at the state level.

4. Using phx42 FID to Detect Leaks and Limit Exposure

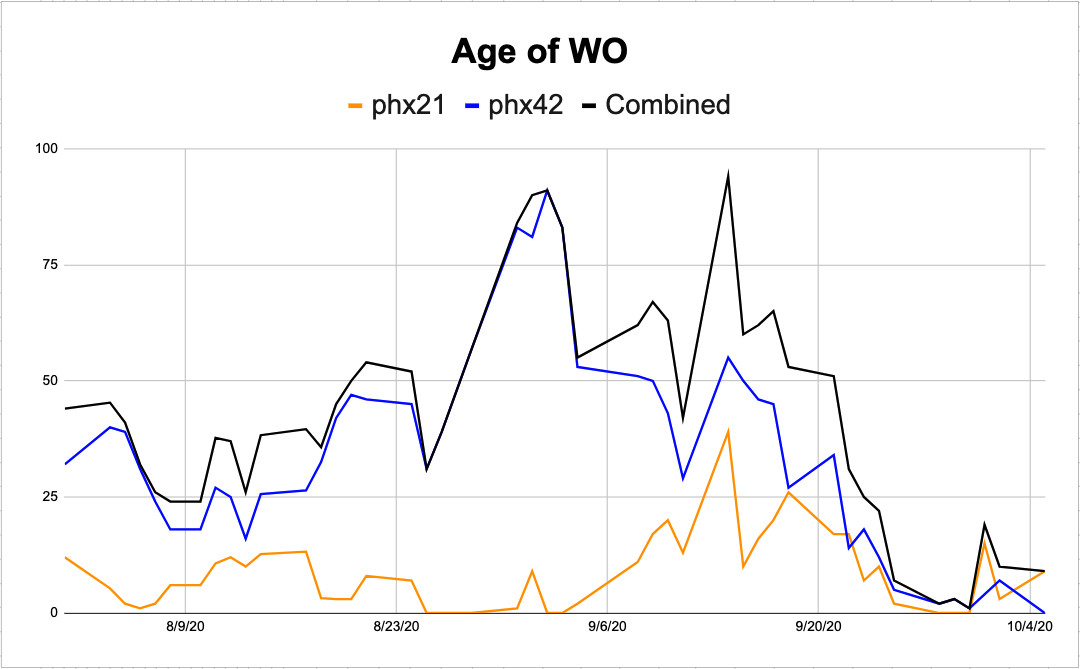

The phx42 Flame Ionization Detector (FID) is an advanced leak detection technology that helps industries reduce EtO emissions and limit human exposure to this hazardous substance. The device works by detecting organic compounds like EtO in the air and providing accurate, real-time measurements of their concentrations.

By utilizing the phx42 FID to identify and locate leaks in the equipment and processes that handle EtO, industries can quickly address and repair these issues, minimizing the release of EtO into the environment. This, in turn, leads to reduced emissions and improved air quality, thus protecting the health of workers and surrounding communities.

The use of advanced detection technologies like the phx42 FID is essential in ensuring the effectiveness of EPA regulations and meeting emission reduction goals. Moreover, these tools contribute to the ongoing efforts of industries to minimize their environmental impact and protect public health.

Conclusion:

EPA regulations on EtO emissions have had a significant positive impact on air quality and public health. By establishing strict standards and consistently enforcing them, the EPA has been successful in reducing EtO emissions and limiting human exposure to this hazardous substance. The use of advanced leak detection technologies, such as the phx42 FID, plays a crucial role in identifying and mitigating EtO emissions, contributing to improved air quality and a safer environment. It is essential to continue monitoring and enforcing these regulations to maintain and enhance the progress achieved in air quality improvement, ensuring a healthier future for all.