Understanding the Impact of Filters on Portable FIDs

Filters are a key component in the efficient operation of portable FIDs (Flame Ionization Detectors). Their lifespan depends on usage hours and the environment, with water exposure being a critical factor. Technician diligence in maintaining these filters is crucial for the longevity of portable FIDs.

Our portable FID filters feature a pre-filter layer, enhancing their durability compared to standard 1um filters. This, along with the reduced flow of specific models like the phx42, ensures that filters in portable FIDs last significantly longer.

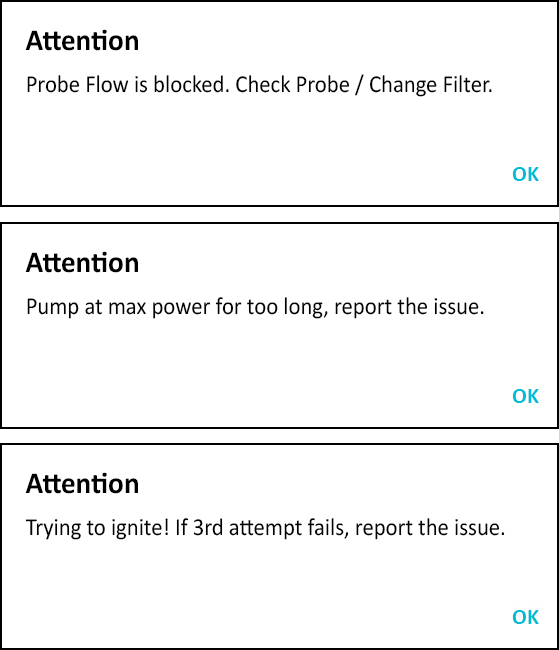

Probes Maintenance in Portable FIDs

Proper maintenance of probes is vital for the consistent performance of portable FIDs. Technician care can prevent frequent replacements. Considering a proactive replacement every six months can be more cost-effective, despite the common practice of only replacing them when leaks occur.

Battery Life in Portable FIDs

Batteries in portable FIDs generally have a lifespan of over three years. While it’s common to replace a battery in one out of six units before then, it’s advisable to buy replacements as needed, as batteries in portable FIDs often last longer while in use.

Glow Disks and Scrubber Media for Portable FIDs

Glow disks in portable FIDs can last long, especially with correct shutdown procedures and maintenance. Planning for one replacement per machine over a three-year period is a good practice. The life of Scrubber Media in portable FIDs also varies based on the operating environment.

Pumps in Portable FIDs

The sample pump, a critical component of portable FIDs, requires attention as it is susceptible to wear from various samples and chemicals. Estimating 1-2 pump replacements per machine over 3 years is a safe bet, although this can vary based on usage.

Final Thoughts on Portable FID Maintenance

Due to the variability in treatment and environment, maintaining portable FIDs can be challenging. Averages for maintenance schedules are often unreliable. Opting for an extended warranty could be a wise decision for ensuring the longevity and reliability of portable FIDs.

Disclaimer: This guide is based on general use cases of portable FIDs and may vary depending on specific conditions and handling of the equipment.

*This is a misnomer, but also a term the industry has accepted to describe portable FIDs.